Custom printed T-shirts bring numerous benefits to small business marketing and promotional campaign. With their ability to maximum brand awareness, enhance credibility, and foster community. Additionally, their affordable price makes them an accessible strategy for small businesses working within tight budgets.

So, Custom printing service has become a vital role in business competitions of apparel manufacturing industry. The manufacturers must have rich experiences and advanced equipment to turn customer’s design into a reality. There are many of printing methods to get your designs printed, from direct-to-garment printing and silk screening to sublimation and more.

Direct-to-garment printing (DTG printing)

As the name implies, direct-to-garment is a t-shirt printing technique that applies inks directly to t-shirts, and this distinguishes it from t-shirt printing techniques that apply inks indirectly using a screen or a transfer paper. It offers a versatile and efficient way to produce high-quality, custom apparel with intricate designs

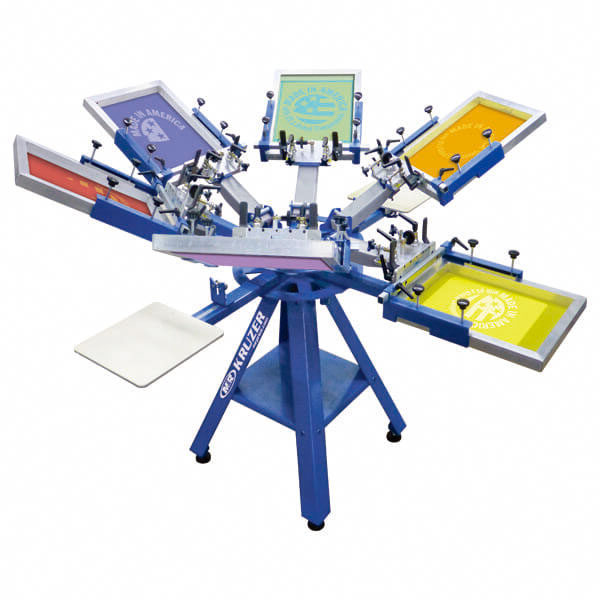

Silk screen printing

The screen printing technique, also called silkscreen printing, applies ink designs to shirts by pressing ink through a mesh partly blocked off by a stencil printing shape. Using a mesh medium classifies screen printing as an indirect method of getting different types of shirt prints.

It’s a cost-effective method for large quantities, and its ability to print on a wide variety of materials and surfaces makes it suitable for many applications, from clothing and packaging to signage and industrial products.

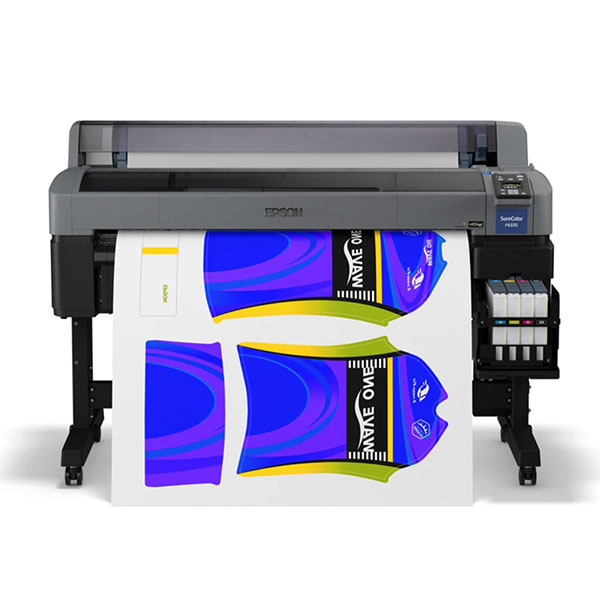

Dye sublimation printing

The sublimation process is when sublimation dyes are printed onto a transfer medium with a specially prepared inkjet printer. Afterward, dyes are then transferred from the medium to an object or garment under the heat and pressure delivered by a commercial heat press. When the heat and pressure are applied, the dye on the transfer medium sublimates, or becomes a gas, and is then absorbed into the polyester itself; the print is actually a part of the garment/coating. The ink infuses with the fabric itself, creating a more cohesive benefit.

Heat transfer printing

Heat transfer vinyl printing, also known as iron-on printing, transfers designs from vinyl plastic-based sheets. You color one side of the sheet with removable tape and cut it into design shapes. You coat the other side with an adhesive activated by heating.

It’s a popular choice for creating custom apparel, promotional items, and personalized products due to its ability to produce vibrant, durable, and detailed prints.

When choosing among the different t-shirt printing methods for your business, consider the design complexity, fabric type, order volume, and budget.

We can meet your requirements which require tight turnaround times and budgets. Feel free to contact us get more information!